About Us

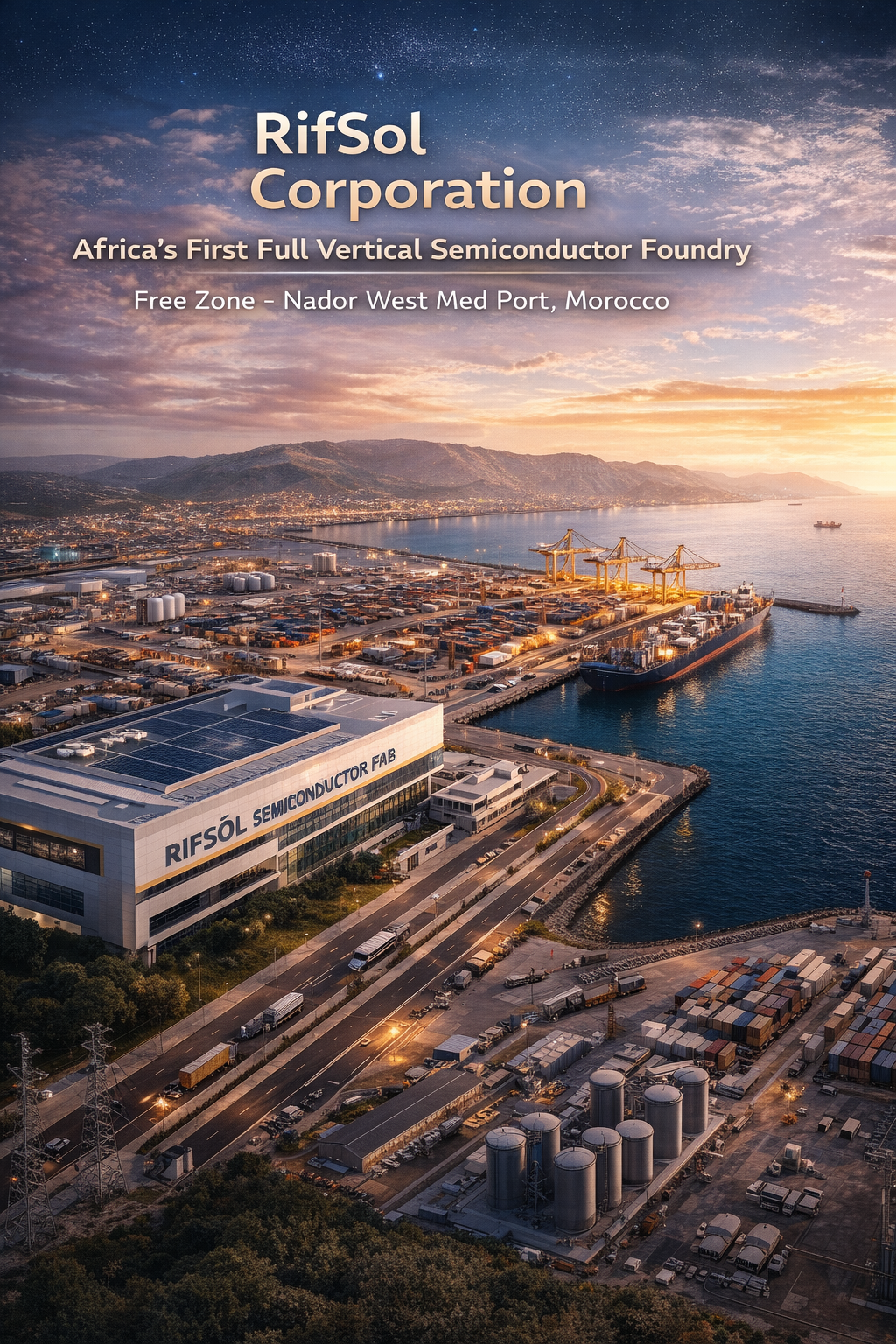

About RifSol Corporation

At RifSol Corporation, we are committed to establishing Africa's semiconductor sovereignty through innovative solutions and cutting-edge technology, transforming industries across the continent and globally.

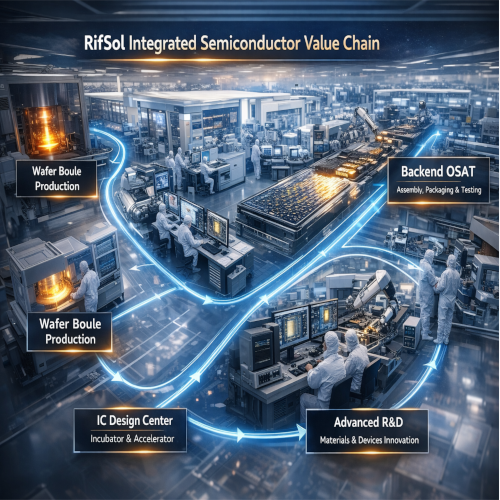

We cover the entire semiconductor production process, from wafer production and IC design to photolithography and packaging.

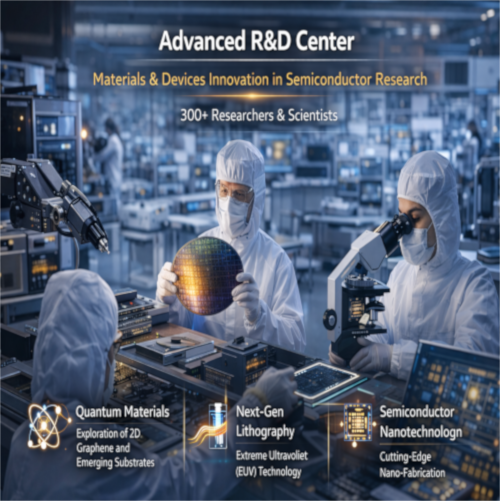

Our state-of-the-art R&D center drives innovation in semiconductor materials, 3D printing and advanced packaging and process optimization.

RifSol Corporation is equipped to serve international markets seamlessly, thanks to our strategic location in Morocco, and our OSATs world wide.

Commitment to Quality

RifSol Corporation is dedicated to environmentally friendly practices, emphasizing renewable energy integration and sustainability throughout our operations.

We actively participate in initiatives that educate and empower our communities, ensuring that the semiconductor industry benefits all.

To be the leading semiconductor foundry in Africa, propelling technological advancements and fostering global partnerships.

Get in Touch

Our Portfolio

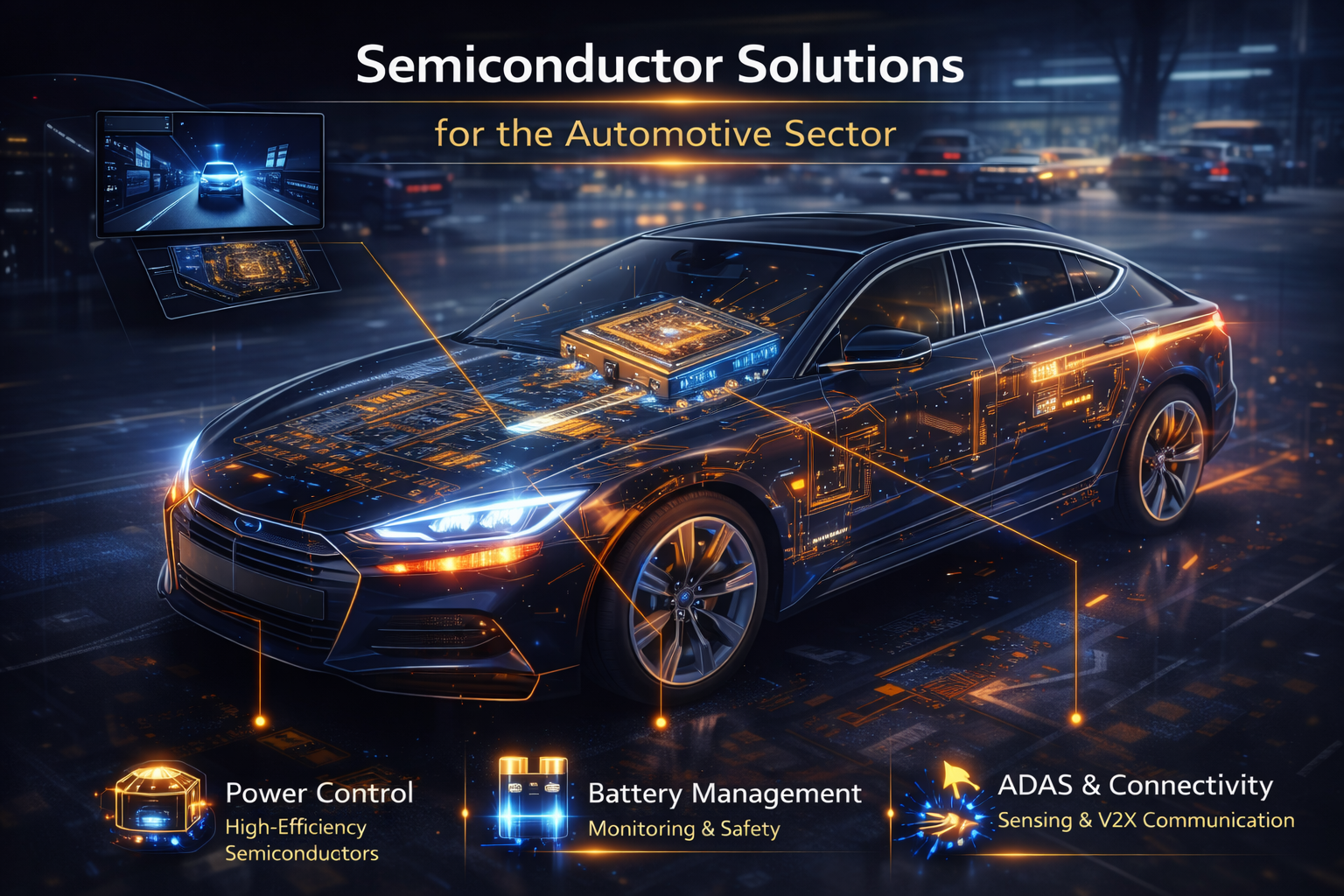

Semiconductor Solutions for the EV Sector

We're transforming automotive electronics with our advanced semiconductor technologies that ensure safety and efficiency.

Innovative Solar Power Applications

Our HJT solar cells are being utilized to enhance energy efficiency in upcoming renewable systems for streetlights or the industry.

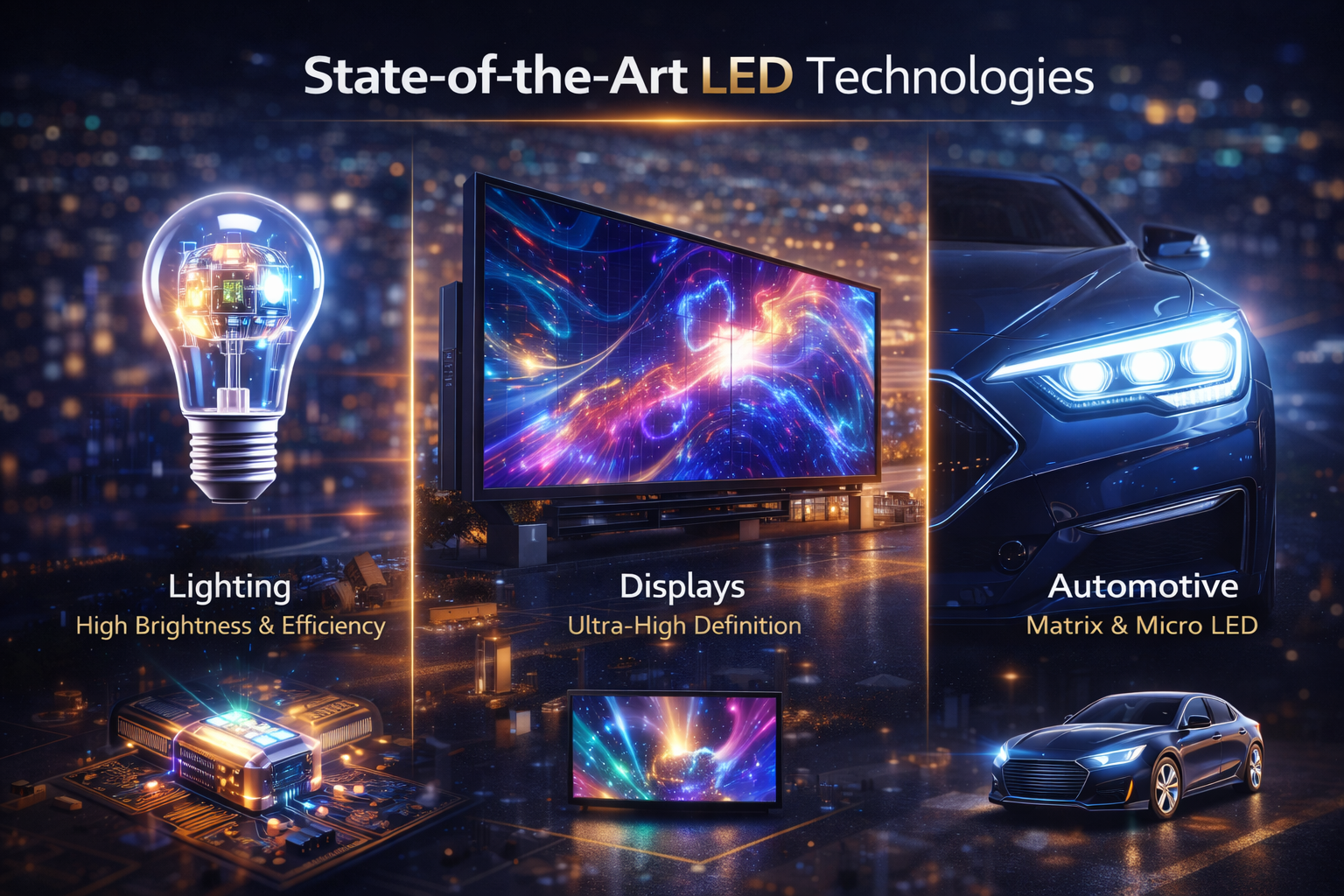

State-of-the-Art LED Technologies

We're developing custom LED solutions for smart cities, enhancing urban technologies and lifestyles powered by Moroccan phosphate.

Comprehensive IC Design Center

Our IC design services are prominent for various applications, from smart devices to complex communication systems.